Disinfectant Tunnel made by DIYANI Engineering

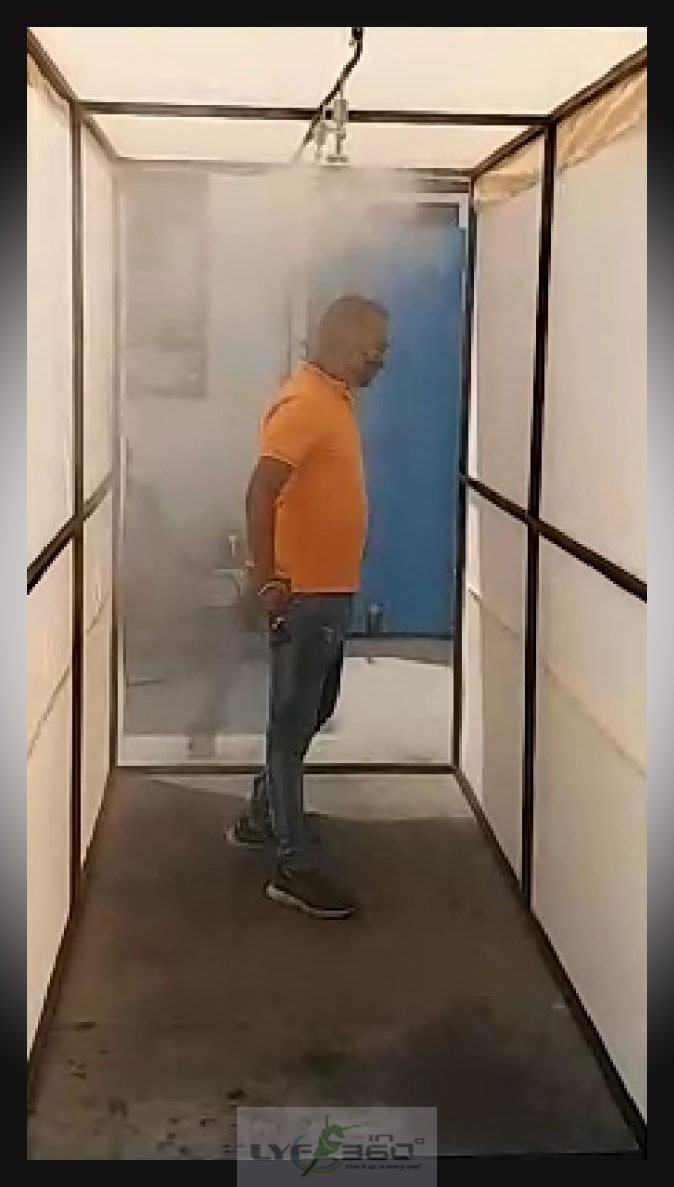

Disinfectant Tunnels or Sanitizing Tunnels are becoming one of the most in-demand commodities in the Covid world with malls, offices, banks, schools, universities, supermarket, airports, hospitals lining up to install the structure at their entrances.

DIYANI Engineering leading packaging machine manufacturer come up with the innovative, cheapest & customized solution for sanitizing/disinfection as per customer need that can be a public value.

In the wake of the coronavirus outbreak disinfectant tunnels are emerging as World’s one of the important strategies.

Disinfection is essential for ensuring that hosts do not transmit infectious pathogens to other person.

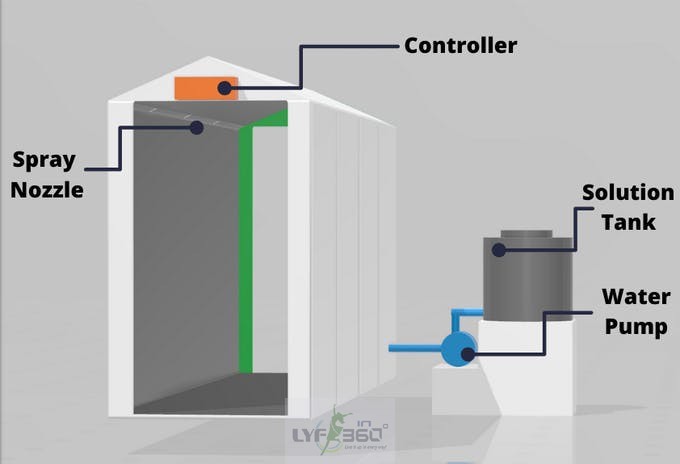

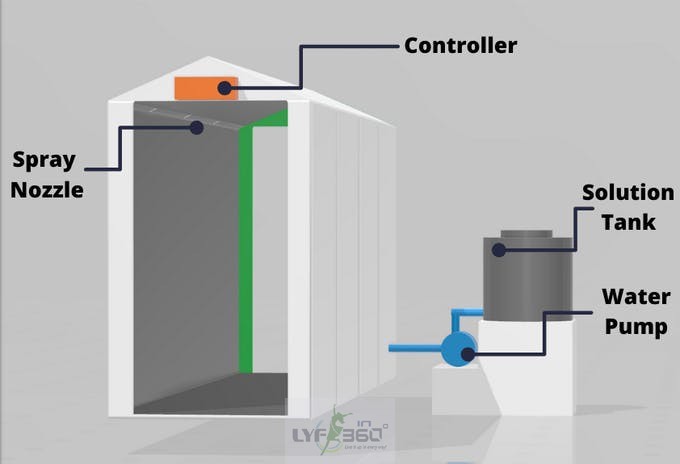

The principle behind this strategy is simple, When a person enters the tunnel, he or she walks through an automatic sterilization spray for a period of 10 seconds which can considerably reduce the number of germs on an individual.

Sanitization Tunnels represent a safe protection and entry for everyone, in particular for those who work in close contact with groups and are therefore at higher risk. It can be installed at the entrance of public offices, , supermarkets, airports, hospitals, ports, stations. It is suitable for all private companies who need to sanitize the workforce, goods, vehicles and materials.

Obvious, there is Cons also, some people are not in favour of using it. The use of disinfectant tunnels can cause harm to humans especially if sodium hypochlorite or chorine are used in tunnels at public spaces. Doctors say sodium hypochlorite can cause skin and eye irritation. The World Health Organisation (WHO) recommends the use of sodium hypochlorite, a key ingredient in bleach, only on surfaces. Health authorities are also raising an alarm.

If we look at pros over cons, it is better solution to disinfect individual in such situation & minimising the risk of spreading infection. Even swimming pool chemicals are harmful. All allopathic medicines are similar way harmful and useful. It’s all are depending on disciplined use & following government’s safety guidelines.

Features of Diyani Disinfectant Tunnel

- Fully Automatic / Manual

- Harmless & Human Friendly

- Motion sensor

- PVC / Steel Structure

- Brass Nozzle

- Sheet / Fabric Covered

- Drying Zone

- Operating Cost 50 Paisa per person

DIYANI Engineering offering you total four model according to your requirement & will work with you to help you choose the perfect size and accessories to suite your needs.

SPECIFICATION

MODEL à | DY- Eco | DY- Eco+ | DY – ST | DY – ST+ |

Structure | Metal | Metal | Metal | Metal |

Size – Feet | 4 x 4 x 8 | 4 x 4 x 8 | 4 x 4 x 8 | 4 x 6 x 8 |

Cover | Vinyl Fabric | Vinyl Fabric | ACP Sheet | ACP Sheet |

Operation | Manual | Auto | Manual | Auto |

Tank | 20 Ltr | 20 Ltr | 20 Ltr | 20 Ltr |

Nozzle | 4 Nos | 4 Nos | 4 Nos | 4 Nos |

Drying Zone | NO | Optional | Optional | YES |

-: Contact for enquiry:-

Regd – I 1703, Elysium, Adani Shantigram, SG Highway, Ahmedabad – 382142 (India).

Works – 124, 127, Fortune Industrial Park, Kathwada GIDC, Ahmedabad- 382350

Phone: +91 93274 80120, 99786 81120

E-mail: sales@diyani.in

Weighing & Packing | Material Handling | Customized Automation |

– Bagging Machine – Packing Machine – Bagging Controller – Silo / tank Weighing – Drum Filling Machine – Check Weigher – Weighing Scale | – Belt Conveyor – Slat Conveyor – Sealing Machine – Stitching machine – Bag turner / pusher – Bag loader / un loader – Screw feeder – Storage Hopper – Dust Collector / Blower | – Power Panel – Control Panel – Process / machine Automation – Batch weighing automation – AMC – Data Logging |

One Response

I have been reading out many of your stories and i can state clever stuff. I will definitely bookmark your site.